Request a Quote

Electric Forklifts 4 to 5t, 4 Wheel – 7 Series

Electric Forklifts 4 to 5t, 4 Wheel – 7 Series

The 7-Series electric forklifts feature exclusive ACT technology, user-driven performance, intelligent torque control, and maintenance-free electric motors. With spacious operator compartments, high visibility, and advanced, programmable controls, these trucks offer reliable performance at a reduced cost.

Request a Quote

Find a Dealer

Download Brochure

Electric Forklifts 4 to 5t, 4 wheel – 7-Series

Electric Forklifts 4 to 5t, 4 Wheel – 7 Series

Electric Forklifts 4 to 5t, 4 Wheel – 7 Series

The 7-Series electric forklifts feature exclusive ACT technology, user-driven performance, intelligent torque control, and maintenance-free electric motors. With spacious operator compartments, high visibility, and advanced, programmable controls, these trucks offer reliable performance at a reduced cost.

Request a Quote

Find a Dealer

Download Brochure

Specifications

Specifications

| B40X-7 | B45X-7 | B50XC-7 | B50X-7 | |

|---|---|---|---|---|

| Rated Load Capacity | 4000 kg | 4500 kg | 4990 kg | 5000 kg |

| Load Center | 500 mm | 500 mm | 500 mm | 500 mm |

| Travel Speed, Unloaded | 16 km/h | 16 km/h | 16 km/h | 16 km/h |

| B40X-7 | B45X-7 | B50XC-7 | B50X-7 | |

|---|---|---|---|---|

| Drive: electric (battery or mains) | Electric | Electric | Electric | Electric |

| Operator type | Driver seated | Driver seated | Driver Seated | Driver Seated |

| Load capacity/rated load | 4000 kg | 4500 kg | 4990 kg | 5000 kg |

| Load centre distance | 500 mm | 500 mm | 500 mm | 500 mm |

| Load distance, centre of drive axle to fork | 572 mm | 572 mm | 572 mm | 572 mm |

| Wheelbase | 2000 mm | 2000 mm | 2000 mm | 2000 mm |

| B40X-7 | B45X-7 | B50XC-7 | B50X-7 | |

|---|---|---|---|---|

| Service weight (with min. weight of battery) | 7012 kg | 7427 kg | 7734 kg | 7763 kg |

| Axle loading, loaded front/rear | 9874/1138 kg | 10607/1320 kg | 11415/1318 kg | 11450/1312 kg |

| Axle loading, unloaded front/rear | 3730/3282 kg | 3695/3732 kg | 3735/3998 kg | 3770/3992 kg |

| B40X-7 | B45X-7 | B50XC-7 | B50X-7 | |

|---|---|---|---|---|

| Tires: pneumatic (P), superelastic (SE), cushion (C) | SE | SE | SE | SE |

| Tire size, front | 250 - 15 | 28x12.5 - 15 | 28x12.5 - 15 | 28x12.5 - 15 |

| Tire size, rear | 7.00 - 12 | 7.00 - 12 | 7.00 - 12 | 7.00 - 12 |

| Wheels, number front/rear (x=driven wheels) | 2/2 | 2/2 | 2/2 | 2/2 |

| Tread width, front | 1168 mm | 1160 mm | 1160 mm | 1160 mm |

| Tread width, rear | 1111 mm | 1111 mm | 1111 mm | 1111 mm |

| B40X-7 | B45X-7 | B50XC-7 | B50X-7 | |

|---|---|---|---|---|

| Tilt of mast/fork carriage forward (α)/backward(β) | 6/9 deg | 6/9 deg | 6/9 deg | 6/9 deg |

| Height, mast lowered | 2330 mm | 2340 mm | 2340 mm | 2340 mm |

| Free lift | 150 mm | 160 mm | 160 mm | 160 mm |

| Lift (with STD 2-stage mast) | 3250 mm | 3250 mm | 3250 mm | 3250 mm |

| Lift height | 3300 mm | 3300 mm | 3300 mm | 3300 mm |

| Height, mast extended | 4170 mm | 4180 mm | 4180 mm | 4205 mm |

| Height to top of overhead guard | 2345 mm | 2350 mm | 2350 mm | 2350 mm |

| Seat height/stand height | 1297 mm | 1303 mm | 1303 mm | 1303 mm |

| Towing coupling height | 415 mm | 415 mm | 415 mm | 415 mm |

| Overall length | 4007 mm | 4007 mm | 4037 mm | 4037 mm |

| Length to face of forks | 2975 mm | 2957 mm | 2987 mm | 2987 mm |

| Overall width | 1470 mm | 1470 mm | 1470 mm | 1470 mm |

| Fork dimensions | 50/150/1050 mm | 50/150/1050 mm | 50/150/1050 mm | 50/150/1050 mm |

| Fork carriage ISO 2328. Class/type A, B | III A | III A | III A | IV A |

| Fork carriage width | 1250 mm | 1250 mm | 1250 mm | 1330 mm |

| Fork Spacing (min/max) | 310x1182 mm | 310x1182 mm | 310x1182 mm | 340x1290 mm |

| Ground clearance, with load, below mast | 120 mm | 130 mm | 130 mm | 130 mm |

| Ground clearance, centre of wheelbase | 160 mm | 160 mm | 160 mm | 160 mm |

| Aisle width for pallets 1000x1200 crossways | 4416 mm | 4417 mm | 4442 mm | 4442 mm |

| Aisle width for pallets 800x1200 lengthways | 4655 mm | 4656 mm | 4681 mm | 4681 mm |

| Turning radius | 2620 mm | 2620 mm | 2645 mm | 2645 mm |

| Internal turning radius | 877 mm | 879 mm | 879 mm | 879 mm |

| B40X-7 | B45X-7 | B50XC-7 | B50X-7 | |

|---|---|---|---|---|

| Travel speed, loaded/unloaded | 15/16 km/h | 15/16 km/h | 15/16 km/h | 15/16 km/h |

| Lift speed, loaded/unloaded | 350/470 m/s | 330/470 m/s | 310/470 m/s | 310/470 m/s |

| Lowering speed, loaded/unloaded | 480/450 m/s | 480/450 m/s | 480/450 m/s | 480/450 m/s |

| Maximum drawbar pull, loaded/unloaded, 5 minute rating | 18620/18620 N | 18620/18620 N | 18620/18620 N | 18620/18620 N |

| Maximum gradeability, loaded/unloaded, 5 minute rating | 17/27 % | 16/26 % | 15/25 % | 15/25 % |

| Service brake | FOOT/HYD | FOOT/HYD | FOOT/HYD | FOOT/HYD |

| Parking brake | HAND-MECH/AUTO-ELECTRIC | HAND-MECH/AUTO-ELECTRIC | HAND-MECH/AUTO-ELECTRIC | HAND-MECH/AUTO-ELECTRIC |

| B40X-7 | B45X-7 | B50XC-7 | B50X-7 | |

|---|---|---|---|---|

| Drive motor rating S2 60 minute | 10 X 2 kW | 10 X 2 kW | 10 X 2 kW | 10 X 2 kW |

| Lifting motor rating at S3 15% | 28 kW | 28 kW | 28 kW | 28 kW |

| Battery as per DIN 43531/35/36 A, B, C, no | DIN43536A | DIN43536A | DIN43536A | DIN43536A |

| Battery voltage/nominal capacity K5 | 80/720 V/Ah | 80/720 V/Ah | 80/720 V/Ah | 80/720 V/Ah |

| Battery weight (min) | 2160 kg | 2160 kg | 2160 kg | 2160 kg |

| Battery compartment* L/W/H | 1007/1040/840 mm | 1007/1040/840 mm | 1007/1040/840 mm | 1007/1040/840 mm |

| B40X-7 | B45X-7 | B50XC-7 | B50X-7 | |

|---|---|---|---|---|

| Type of drive control unit | Inverter AC | Inverter AC | Inverter AC | Inverter AC |

| Working press for attachments - System | 190 bar | 210 bar | 230 bar | 230 bar |

| Working press for attachments - Attachment | 155 bar | 155 bar | 155 bar | 155 bar |

| Sound level at the driver’s ear according to EN 12 053 | 70 dB (A) | 70 dB (A) | 70 dB (A) | 70 dB (A) |

| B40X-7 | B45X-7 | B50XC-7 | B50X-7 | |

|---|---|---|---|---|

| Rated Load Capacity | 4000 kg | 4500 kg | 4990 kg | 5000 kg |

| Load Center | 500 mm | 500 mm | 500 mm | 500 mm |

| Travel Speed, Unloaded | 16 km/h | 16 km/h | 16 km/h | 16 km/h |

| B40X-7 | B45X-7 | B50XC-7 | B50X-7 | |

|---|---|---|---|---|

| Drive: electric (battery or mains) | Electric | Electric | Electric | Electric |

| Operator type | Driver seated | Driver seated | Driver Seated | Driver Seated |

| Load capacity/rated load | 4000 kg | 4500 kg | 4990 kg | 5000 kg |

| Load centre distance | 500 mm | 500 mm | 500 mm | 500 mm |

| Load distance, centre of drive axle to fork | 572 mm | 572 mm | 572 mm | 572 mm |

| Wheelbase | 2000 mm | 2000 mm | 2000 mm | 2000 mm |

| B40X-7 | B45X-7 | B50XC-7 | B50X-7 | |

|---|---|---|---|---|

| Service weight (with min. weight of battery) | 7012 kg | 7427 kg | 7734 kg | 7763 kg |

| Axle loading, loaded front/rear | 9874/1138 kg | 10607/1320 kg | 11415/1318 kg | 11450/1312 kg |

| Axle loading, unloaded front/rear | 3730/3282 kg | 3695/3732 kg | 3735/3998 kg | 3770/3992 kg |

| B40X-7 | B45X-7 | B50XC-7 | B50X-7 | |

|---|---|---|---|---|

| Tires: pneumatic (P), superelastic (SE), cushion (C) | SE | SE | SE | SE |

| Tire size, front | 250 - 15 | 28x12.5 - 15 | 28x12.5 - 15 | 28x12.5 - 15 |

| Tire size, rear | 7.00 - 12 | 7.00 - 12 | 7.00 - 12 | 7.00 - 12 |

| Wheels, number front/rear (x=driven wheels) | 2/2 | 2/2 | 2/2 | 2/2 |

| Tread width, front | 1168 mm | 1160 mm | 1160 mm | 1160 mm |

| Tread width, rear | 1111 mm | 1111 mm | 1111 mm | 1111 mm |

| B40X-7 | B45X-7 | B50XC-7 | B50X-7 | |

|---|---|---|---|---|

| Tilt of mast/fork carriage forward (α)/backward(β) | 6/9 deg | 6/9 deg | 6/9 deg | 6/9 deg |

| Height, mast lowered | 2330 mm | 2340 mm | 2340 mm | 2340 mm |

| Free lift | 150 mm | 160 mm | 160 mm | 160 mm |

| Lift (with STD 2-stage mast) | 3250 mm | 3250 mm | 3250 mm | 3250 mm |

| Lift height | 3300 mm | 3300 mm | 3300 mm | 3300 mm |

| Height, mast extended | 4170 mm | 4180 mm | 4180 mm | 4205 mm |

| Height to top of overhead guard | 2345 mm | 2350 mm | 2350 mm | 2350 mm |

| Seat height/stand height | 1297 mm | 1303 mm | 1303 mm | 1303 mm |

| Towing coupling height | 415 mm | 415 mm | 415 mm | 415 mm |

| Overall length | 4007 mm | 4007 mm | 4037 mm | 4037 mm |

| Length to face of forks | 2975 mm | 2957 mm | 2987 mm | 2987 mm |

| Overall width | 1470 mm | 1470 mm | 1470 mm | 1470 mm |

| Fork dimensions | 50/150/1050 mm | 50/150/1050 mm | 50/150/1050 mm | 50/150/1050 mm |

| Fork carriage ISO 2328. Class/type A, B | III A | III A | III A | IV A |

| Fork carriage width | 1250 mm | 1250 mm | 1250 mm | 1330 mm |

| Fork Spacing (min/max) | 310x1182 mm | 310x1182 mm | 310x1182 mm | 340x1290 mm |

| Ground clearance, with load, below mast | 120 mm | 130 mm | 130 mm | 130 mm |

| Ground clearance, centre of wheelbase | 160 mm | 160 mm | 160 mm | 160 mm |

| Aisle width for pallets 1000x1200 crossways | 4416 mm | 4417 mm | 4442 mm | 4442 mm |

| Aisle width for pallets 800x1200 lengthways | 4655 mm | 4656 mm | 4681 mm | 4681 mm |

| Turning radius | 2620 mm | 2620 mm | 2645 mm | 2645 mm |

| Internal turning radius | 877 mm | 879 mm | 879 mm | 879 mm |

| B40X-7 | B45X-7 | B50XC-7 | B50X-7 | |

|---|---|---|---|---|

| Travel speed, loaded/unloaded | 15/16 km/h | 15/16 km/h | 15/16 km/h | 15/16 km/h |

| Lift speed, loaded/unloaded | 350/470 m/s | 330/470 m/s | 310/470 m/s | 310/470 m/s |

| Lowering speed, loaded/unloaded | 480/450 m/s | 480/450 m/s | 480/450 m/s | 480/450 m/s |

| Maximum drawbar pull, loaded/unloaded, 5 minute rating | 18620/18620 N | 18620/18620 N | 18620/18620 N | 18620/18620 N |

| Maximum gradeability, loaded/unloaded, 5 minute rating | 17/27 % | 16/26 % | 15/25 % | 15/25 % |

| Service brake | FOOT/HYD | FOOT/HYD | FOOT/HYD | FOOT/HYD |

| Parking brake | HAND-MECH/AUTO-ELECTRIC | HAND-MECH/AUTO-ELECTRIC | HAND-MECH/AUTO-ELECTRIC | HAND-MECH/AUTO-ELECTRIC |

| B40X-7 | B45X-7 | B50XC-7 | B50X-7 | |

|---|---|---|---|---|

| Drive motor rating S2 60 minute | 10 X 2 kW | 10 X 2 kW | 10 X 2 kW | 10 X 2 kW |

| Lifting motor rating at S3 15% | 28 kW | 28 kW | 28 kW | 28 kW |

| Battery as per DIN 43531/35/36 A, B, C, no | DIN43536A | DIN43536A | DIN43536A | DIN43536A |

| Battery voltage/nominal capacity K5 | 80/720 V/Ah | 80/720 V/Ah | 80/720 V/Ah | 80/720 V/Ah |

| Battery weight (min) | 2160 kg | 2160 kg | 2160 kg | 2160 kg |

| Battery compartment* L/W/H | 1007/1040/840 mm | 1007/1040/840 mm | 1007/1040/840 mm | 1007/1040/840 mm |

| B40X-7 | B45X-7 | B50XC-7 | B50X-7 | |

|---|---|---|---|---|

| Type of drive control unit | Inverter AC | Inverter AC | Inverter AC | Inverter AC |

| Working press for attachments - System | 190 bar | 210 bar | 230 bar | 230 bar |

| Working press for attachments - Attachment | 155 bar | 155 bar | 155 bar | 155 bar |

| Sound level at the driver’s ear according to EN 12 053 | 70 dB (A) | 70 dB (A) | 70 dB (A) | 70 dB (A) |

Features

Features

Curtis AC controllers provide an unbeatable combination of power, performance and functionality.

- Driving and hydraulics are controlled by a AC controller to deliver fast and powerful performance.

- Reduced operating costs are achieved by the elimination of motor brushes, commutators, directional, and hydraulic contactors.

- Energy consumption efficiency translates into more run time per battery charge.

The transaxle efficiently transfers the power and torque from the drive motor to the final drive for seamless and quiet operation.

The IP54 rating protects the motor and its components against liquids from any direction, even in the rain.*Drive motor IP54 / Hydraulic motor IP20.

For more efficient acceleration and braking, initial speeds are reduced to ensure safe and comfortable movement, while acceleration during mid and high-speeds is increased to enhance operational productivity; additionally, braking pedal effort is decreased.

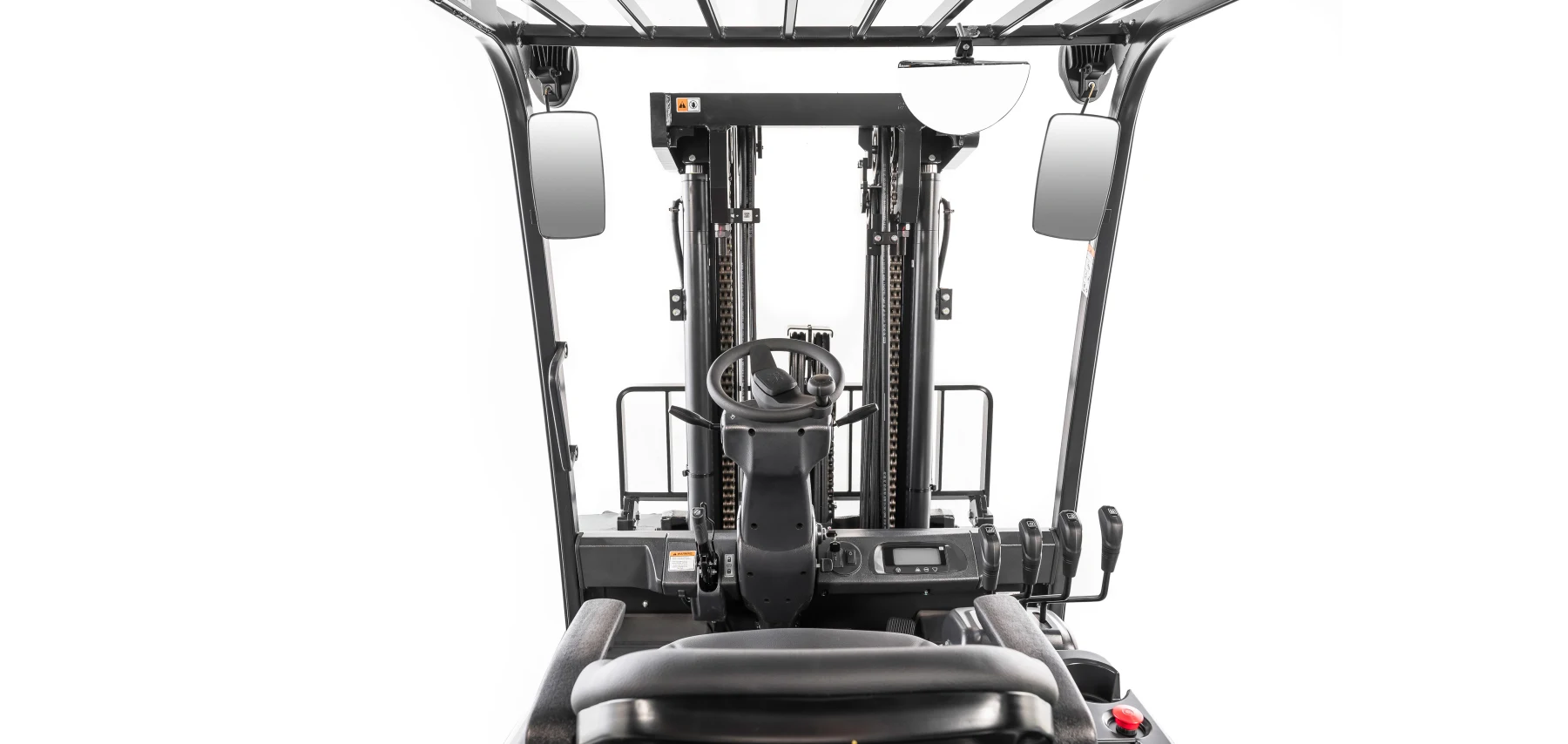

The wider mast window, neatly arranged hydraulic hoses and chains, and flat overhead guard ensure a clear view of the surroundings, including forward, upward, and to the load.

The directional switch is positioned on the hydraulic lever for swift transitions between forward and backward movements.

The steering wheel's compact design reduces operator fatigue.

The operator can adjust the position of the column for convenience and comfort.

The Anti-Slip Step and Entry Bar makes it easier to get on and off the truck.

Operators can simply control the truck’s performance with the easy and intuitive instrument panel.

The Grammer suspension seat is fully adjustable to accommodate every individual.

Operators can pre-select travel speeds without affecting the lifting speed, ensuring safe maneuverability in delicate operating situations.

The thick and large rubber floor mat and rounded hood provide the operator with more legroom.

The operator can quickly push the emergency switch on the steering wheel using only one hand if needed.

The panoramic mirror increase the operator's range of vision, reducing accidents and unnecessary damage to the truck, products, or rack system.

The controller prevents the forklift from rolling back for 5 seconds when the truck is stopped on a slope.

The truck automatically reduces travel speed to the optimal speed when cornering, reducing the risk of accidents or damage.

The horn on the rear grab bar improves safety while traveling in reverse, allowing the operator to alert others while maintaining full control of the vehicle.

The parking alarm prompts operators to apply the parking brake before leaving their seats, while the seat belt indicator activates a 10-second warning light, reminding them to fasten their seatbelts. For additional safety, the intelligent neutral shift feature automatically shifts the forklift into neutral if the operator leaves the seat while the engine is running.

If the operator leaves the seat or turns off the forklift, the tilt, lift, and lowering functions will be disabled.

The wider mast window, neatly arranged hydraulic hoses and chains, and flat overhead guard ensure a clear view of the surroundings, including forward, upward, and to the load.

Compact Steering Wheel.

The controller prevents the forklift from rolling back for 5 seconds when the truck is stopped on a slope.

The truck automatically reduces travel speed to the optimal speed when cornering, reducing the risk of accidents or damage.

The panoramic mirror increase the operator's range of vision, reducing accidents and unnecessary damage to the truck, products, or rack system.

The horn on the rear grab bar improves safety while traveling in reverse, allowing the operator to alert others while maintaining full control of the vehicle.

If the operator leaves the seat or turns off the forklift, the tilt, lift, and lowering functions will be disabled.

The parking alarm prompts operators to apply the parking brake before leaving their seats, while the seat belt indicator activates a 10-second warning light, reminding them to fasten their seatbelts. For additional safety, the intelligent neutral shift feature automatically shifts the forklift into neutral if the operator leaves the seat while the engine is running.

Operators can pre-select travel speeds without affecting the lifting speed, ensuring safe maneuverability in delicate operating situations.

All of the 1.5-3.5t series forklifts feature virtually maintenance-free Oil-Cooled Disc Brakes. Their enclosed design prevents outside contamination, extending brake life up to 5 times longer compared to conventional shoe brakes. This system also comes with our exclusive extended warranty, guaranteeing long-lasting and reliable performance.

The forklift's side cover and footplate can be easily removed without any tools, simplifying service calls.

Easily check brake oil levels using the warning indicator on the instrument panel's display.

Examine forklift health quickly with just our EasyView software and your laptop.

The wider hood opening allows for easier engine access.

The forklift's side cover and footplate can be easily removed without any tools, simplifying service calls.

Curtis AC controllers provide an unbeatable combination of power, performance and functionality.

- Driving and hydraulics are controlled by a AC controller to deliver fast and powerful performance.

- Reduced operating costs are achieved by the elimination of motor brushes, commutators, directional, and hydraulic contactors.

- Energy consumption efficiency translates into more run time per battery charge.

The transaxle efficiently transfers the power and torque from the drive motor to the final drive for seamless and quiet operation.

The IP54 rating protects the motor and its components against liquids from any direction, even in the rain.*Drive motor IP54 / Hydraulic motor IP20.

For more efficient acceleration and braking, initial speeds are reduced to ensure safe and comfortable movement, while acceleration during mid and high-speeds is increased to enhance operational productivity; additionally, braking pedal effort is decreased.

The wider mast window, neatly arranged hydraulic hoses and chains, and flat overhead guard ensure a clear view of the surroundings, including forward, upward, and to the load.

The directional switch is positioned on the hydraulic lever for swift transitions between forward and backward movements.

The steering wheel's compact design reduces operator fatigue.

The operator can adjust the position of the column for convenience and comfort.

The Anti-Slip Step and Entry Bar makes it easier to get on and off the truck.

Operators can simply control the truck’s performance with the easy and intuitive instrument panel.

The Grammer suspension seat is fully adjustable to accommodate every individual.

Operators can pre-select travel speeds without affecting the lifting speed, ensuring safe maneuverability in delicate operating situations.

The thick and large rubber floor mat and rounded hood provide the operator with more legroom.

The operator can quickly push the emergency switch on the steering wheel using only one hand if needed.

The panoramic mirror increase the operator's range of vision, reducing accidents and unnecessary damage to the truck, products, or rack system.

The controller prevents the forklift from rolling back for 5 seconds when the truck is stopped on a slope.

The truck automatically reduces travel speed to the optimal speed when cornering, reducing the risk of accidents or damage.

The horn on the rear grab bar improves safety while traveling in reverse, allowing the operator to alert others while maintaining full control of the vehicle.

The parking alarm prompts operators to apply the parking brake before leaving their seats, while the seat belt indicator activates a 10-second warning light, reminding them to fasten their seatbelts. For additional safety, the intelligent neutral shift feature automatically shifts the forklift into neutral if the operator leaves the seat while the engine is running.

If the operator leaves the seat or turns off the forklift, the tilt, lift, and lowering functions will be disabled.

The wider mast window, neatly arranged hydraulic hoses and chains, and flat overhead guard ensure a clear view of the surroundings, including forward, upward, and to the load.

Compact Steering Wheel.

The controller prevents the forklift from rolling back for 5 seconds when the truck is stopped on a slope.

The truck automatically reduces travel speed to the optimal speed when cornering, reducing the risk of accidents or damage.

The panoramic mirror increase the operator's range of vision, reducing accidents and unnecessary damage to the truck, products, or rack system.

The horn on the rear grab bar improves safety while traveling in reverse, allowing the operator to alert others while maintaining full control of the vehicle.

If the operator leaves the seat or turns off the forklift, the tilt, lift, and lowering functions will be disabled.

The parking alarm prompts operators to apply the parking brake before leaving their seats, while the seat belt indicator activates a 10-second warning light, reminding them to fasten their seatbelts. For additional safety, the intelligent neutral shift feature automatically shifts the forklift into neutral if the operator leaves the seat while the engine is running.

Operators can pre-select travel speeds without affecting the lifting speed, ensuring safe maneuverability in delicate operating situations.

All of the 1.5-3.5t series forklifts feature virtually maintenance-free Oil-Cooled Disc Brakes. Their enclosed design prevents outside contamination, extending brake life up to 5 times longer compared to conventional shoe brakes. This system also comes with our exclusive extended warranty, guaranteeing long-lasting and reliable performance.

The forklift's side cover and footplate can be easily removed without any tools, simplifying service calls.

Easily check brake oil levels using the warning indicator on the instrument panel's display.

Examine forklift health quickly with just our EasyView software and your laptop.

The wider hood opening allows for easier engine access.

The forklift's side cover and footplate can be easily removed without any tools, simplifying service calls.

Similar Machines

Similar Machines

Diesel Forklifts

Bobcat diesel forklifts are the cornerstone of our business with a focus on delivering simple, powerful, and efficient machines while providing the best possible value for our customers. We use high-performance diesel engines that are the greenest on the market.

Learn More

LPG Forklifts

Bobcat LPG trucks are rugged, powerful, and reliable. Our flagship 7-Series offer advanced features like oil-cooled disc brakes, a rear-view camera, auto tilt leveling and a weight scale as standard. By using proven technology, we ensure efficient work while keeping total cost of ownership down for our customers.

Learn More